Chemical residues in agricultural products: how to eliminate them?

Chemical residues in horticultural produce and soil

Until a few years ago, the problem of chemical residues in a crop, its produce or in soil substrates was not taken into consideration. The fruit and vegetable supply chain and also the consumer itself were not interested about the issue, lacking a widespread sensitivity in this regard. As a consequence, farmers often underestimated the need to eliminate these chemical residues because it was considered non-remunerative compared to other commercially observable parameters such as size, colouration, d egrees Brix, etc.

Pink Lady apples treated with BioAksxter® , free of chemical residues

Residue free farming: more income with less products waste. It is possible

The idea of reducing the chemical residues from the agricultural products, in the last years, has been increasingly appreciated by the farmers as it has proved to be an additional source of income: why?

- More restrictive rules regarding the detection of chemical residues

The farmers who deal with the MMR (Mass Market Retailers) directly or through consortia are generally, by contracts, required to observe more restrictive rules regarding the chemical residues due to national and EU restrictions.

Some of these restrictions concern a number of active substances that, if detected in the agricultural products, regardless of the concentration (even extremely low values, but detectable in the analyses) are considered not compliant to the MMR’s standards and the products can not be sell to them but only to the free market at a lower price. This situation also implies penalties, such as the suspension of the supplies for a limited time or in the worse case it can compromise the business relationships.

Considering the risks and limitations, farmers often use the least possible number of active substances; but this may not be sufficient as it does not reduce the risk of external contaminations resulting from the use of those substances by neighbouring farms (“drift effect”). For example, in 2017, some German fruit farmers have been contested by the MMR because the Chlorpyrifos was detected in their apples: the drift effect from the neighbouring vineyards treated with Chlorpyrifos was sufficient to contaminate the apple orchard and trigger the dispute.

Golden Delicious apples treated with BioAksxter® completely residue free -

The time necessary to remove the chemical residues

The periodical list update regarding the plant protection products allowed in agriculture, does not consider the soil “memory” and the time needed by the soil to reduce the residues of these substances. In fact, the wide use of certain active molecules build up in the soil and contaminate the crops produced later, making them non-tradable. - Organic farming: the drift effect and the buffer zones

The certifying bodies require organic farmers not to commercialise as organic products the productions made within the buffer zones at the borders with non-organic farms. However, the buffer zones are not always enough to protect the crops from contaminations because of multiple variables (height of the rows, winds, etc.). In some cases the organic farmers have the organic certification suspended because of contamination from neighbouring farms. To avoid risks, many farmers voluntarily expand the buffer zones, but if in one hand it gives more protection, in the other it means reducing profits. - Agricultural produce free of chemical residues

Some buyers are not satisfied just with the organic certifications and are aware of the chemical contamination that happens to agricultural products, so they look for organic produce also accompanied by analysis attesting that the produce is free from chemical residues.

Potatoes grown with BioAksxter®: free of chemical residues

Removal of chemical residues with BioAksxter®

Issues such as those mentioned above are solved through the use of BioAksxter®:

- It avoids the detection in agricultural products of an excessive amount of active substances, intentionally used or linked to accidental contamination;

- the use of BioAksxter® decontaminates the soils, also from polluting substances accumulated over the years;

- Organic farmers using BioAksxter® can collect all the crops in complete safety, without the need of enlarging the buffer zones.

The following are three case history of different agricultural contexts with the achieved results:

2012 – Case history n.1 – Apples free of pesticides: removal of chemical residues

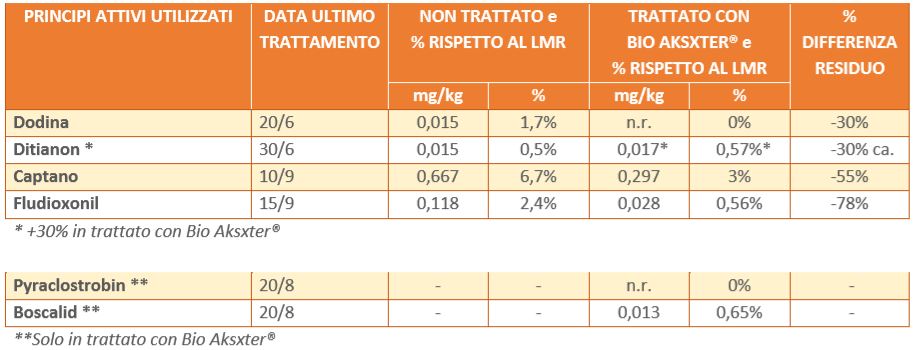

The first case concerns the multi-residual analysis of Golden Delicious apples from a conventional fruit farm in Trento province (Italy). Specifically, the company has been using BioAksxter® regularly for three years and use a total of 20 active substances for crop protection.

Before harvesting, the last treatment was carried out with BioAksxter® and Delan®, a product based on Ditianon (a molecule widely used especially during the spring season that is retained for 21 days after the application).

Golden Delicious apples treated with BioAksxter® completely residue free

From the multi-residual analyses, it emerges that:

- No residues of all the active ingredients used during the spring and summer seasons;

- The amount of Ditianon detected in the samples analysed 10 days after the treatment and 11 days before the end of the retaining time, is equal to 0.64 mg/kg (1/5 of the maximum allowed limit of 3.00 mg/kg).

2014 – Case history n.2 – Ready to eat veggies: reduction of chemical residues accumulated in the soil

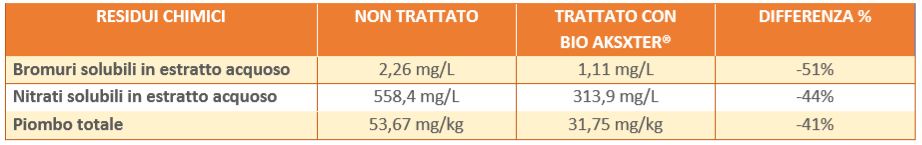

This case is about a conventional farm, operating in protected cultivations and producing leaf vegetables intended for the ready to eat market. Because of the farmer’s past use of methyl bromide and fertilisers of various kinds, their productions were at risk of non-conformity due to the detection of lead, bromide and nitrates beyond the limits. Based on this case specifics, ASX M31 specialists issued an appropriate intervention plan with BioAksxter®. Six weeks after the intervention started, soil samples from the soil treated with BioAksxter® and a sample from an untreated lot were collected and analysed.

Valerian plant treated with BioAksxter®

The multi-residual analyses showed that the use of Bio Aksxter® leads to a significant reduction of bromides, nitrates and lead compared to the initial condition. The following are the tests results:

Soil analysis 6 weeks after the intervention plan with BioAksxter® started

Reduction of chemical residues after six weeks: comparison between soil treated with BioAksxter® and soil untreated

2017 – Case history n.3 – Apples free of pesticides: chemical residues removal from the first treatment

Pink Lady® apple orchard treated with BioAksxter®

The third case is about a conventional farm located in Val di Non (Trento province), Italy. The case highlights BioAksxter® capacity to break down pesticide residues during the first year of treatments. Two lots were planted with apple trees, and both received similar phytosanitary interventions however BioAksxter® was used just in one plot. The plot where BioAksxter® was used, had an additional application of Pyraclostrobin, Boscalid, and 30% more Ditianon than usual. A few weeks later, at the time of harvest, the samples of both plots were analysed. The values of pesticide residues detected in the samples grown with BioAksxter® was significantly lower than the other plot, especially regarding those substances used near the harvest.

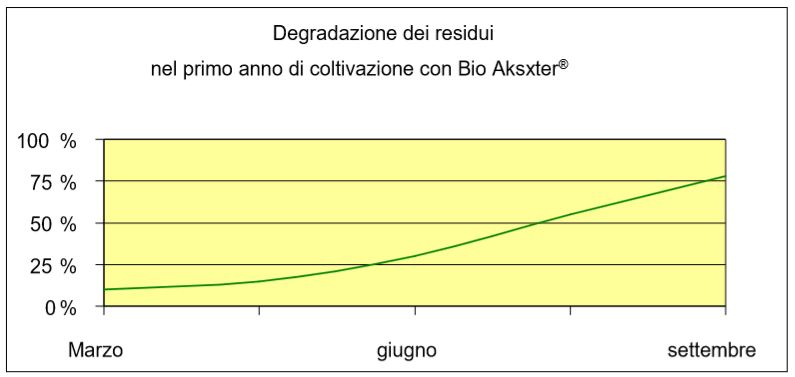

After the first 4 months of treatment, the difference in the percentage of chemical residues between the treated and untreated products is considerable (about 30%); after six months, this gap is even more significant, with a difference of over 60%. From the analysis of the data obtained, therefore, it can be affirmed that with the increase of time BioAksxter® accelerates the process of degradation of chemical residues in agricultural products.

Residual degradation in relation to the period of treatment with BioAksxter®

Field experiences. Consolidated results. Zero residues in agricultural products.

Apple orchards treated with BioAksxter® in excellent vegetative state

The process of chemical residues removal, activated by BioAksxter®, occurs in relation to two variables: time and dose used. The field experience acquired over the years highlighted that the time factor has the greatest impact on the final results. Using BioAksxter® regularly throughout the plant’s vegetative development ensures the best results: a crop that has been treated for long with BioAksxter® eliminate the chemical residues faster.

Also, the application of BioAksxter® at higher doses accelerate the process; it has been tested in cases where BioAksxter® was used after accidental contaminations, erroneous pesticides overdosage and also in cases where there was a need of reducing the accumulated chemicals substances in the soil.